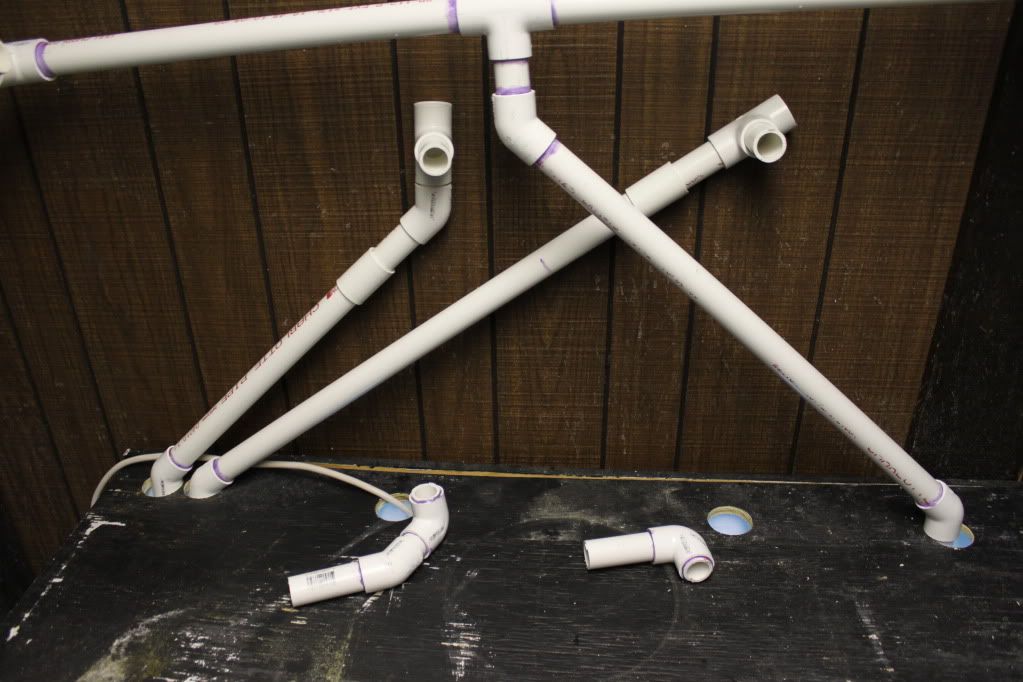

this is a photo of the above plumbing as it stood with the other tank. The problem i ran in to was sound. i did not think it would be an issue because the water was dropping such a short distance in to the overflow. i did not take in to account a need for air. an example of what was happening was a full two liter pop bottle turned upside down. The pipe was sucking air in between water going down it resulting in a lot of noise. the way i remedied this was to add a ball valve and more pipe on the return line back in to the sump add some flow. this allowed me to dial in the top feed, and keep it just under the point where it was making a lot of noise.

Part of the tank 2.0 is to employ a similar tactic to the Durso standpipes but on the outside of the tank. this will allow the water to flow freely while still allowing air to enter. these are not yet finished i will be adding more pipe so they are above the watter level just in case. also will be adding caps with a bunch of holes in an attempt to keep things out dust bugs....

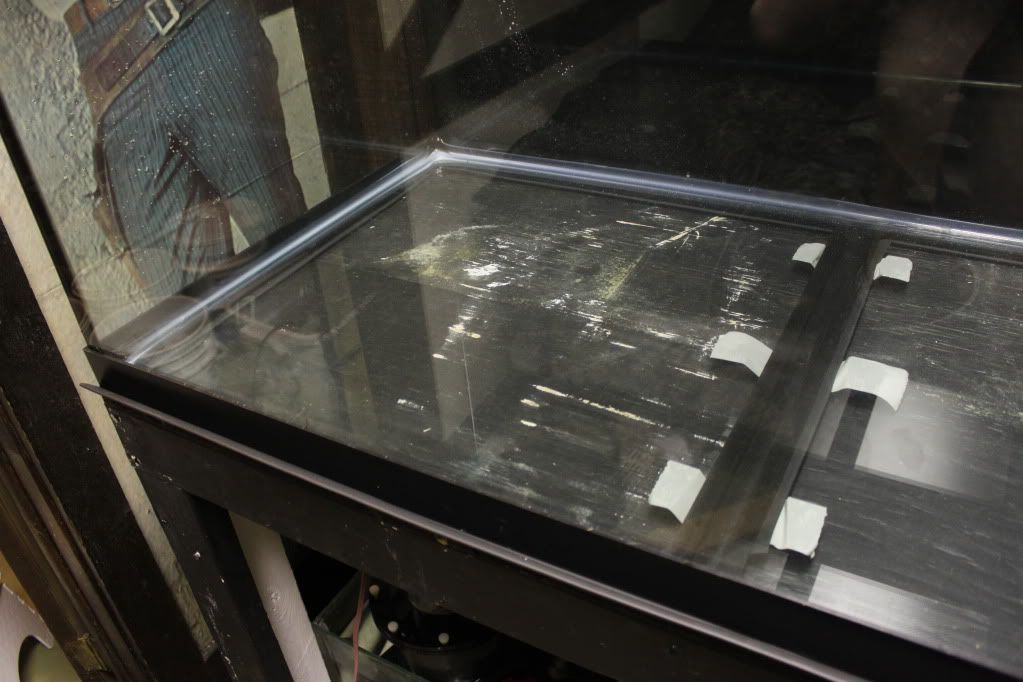

As i am unsure of the reason the old tank leaked i wanted to take as many precautions as possible. The stand was level aside from one side being slightly raised. this only effected the water line and overflow. with the help of my father i leveled the stand. also he proposed that we check to make sure the board was flat. we did find out there was a little bow in a few places. for this we used more "shims" to support areas that were dropping down. I say "shims" because we figured out how much we needed to raise the tank and then cut and or sanded boards rather then using shims. my father suggested some sort of forgiving material be placed under the tank such as rubber. the thought behind this was where the tank makes contact with the stand are not all perfectly the same. due to this different parts of the base of the tank are in contact and others are not. we went to home depot and asked for rubber strips and of course they didnt have them. when we explained the idea and what we were trying to accomplish we received a crazy look and were directed to the hardware isle? am i the only on who receives crazy looks when i go out to buy parts for my projects? most of the things i do are custom and i am capable of explaining what i am trying to accomplish almost all of the people i interact with at these types of stores are not able to think outside of the box. example when i went to home depot i asked an associate about the new pro caulk tool's (discussed in above post) effectiveness i started talking about how i was going to caulking a fish tank and i received a crazy look. i immediately switched to caulking a tub and the guy wouldn't stop talking. He couldnt tell me that it would make nice straight lines on a fish tank but it will for a tub. sorry for the tangent. i ended up with this DIY/ custom curse from my father so i was in good company in searching for something to put under my tank. We decided upon a foam strip used to weather seal garage doors.

Next came filling the tank back up.

this took a little bit of time because i had to wait for the dust to settle so to speak. here are some photos of the aquascapeing i had finished just two weeks ago. sorry not great photos i took them to document it quickly. did not figure i would have to redo it. glad i did though otherwise i would have no document of the 12-16 hours of work i put in to it.

[Timezone Detection]

Create Account - Join in Seconds!

Hybrid View

-

02-01-2010, 03:46 PM #1CR Member

- Join Date

- Jan 2010

- Location

- Michigan

- Posts

- 52

- First Name

- Eric

-

02-01-2010, 03:47 PM #2CR Member

- Join Date

- Jan 2010

- Location

- Michigan

- Posts

- 52

- First Name

- Eric

now to the task of remaking my rock work. below are the tools i used.

this is the start of my aquascapeing

this photo is what happens when you drop a razor blade that you were using to cut the zip ties in to the tank and loose it. i found after a very long time of searching i had to tear apart all of the progress i had made. once i pulled it apart i was still not able to find the blade. i then grabbed one of my koralia 4's and moved it around the bottom of the tank until it grabbed the blade with the magnet.

this is where i ended last night around 1 got a lot of the hard part done and i have a nice plan of attack for tonight. i am really hopping i can finish my aquascapeing tonight. one thought i was originally using the two part plummers epoxy and it does not work at all. i was able to accomplish a little with it but it was much more two steps forward one step back. in my opinion zip ties are the way to go, if you are smart about it they can be used and virtually unseen and add a lot of structural stability. i think my plan is to use some of the plummers epoxy to glue small rock pieces over the zip ties. this way the epoxy is not load bearing so it might work better?

-

02-01-2010, 06:56 PM #3

Awesome awesome awesome, keep the updates and pictures coming!!!

"We shouldn't think of an environment where livestock can survive, we should ensure an environment where livestock can thrive."-Rabidgoose

"If it's gonna be that kinda party, Ima stick my ........ in the mashed potatoes!"-Beastie Boys

Reply With Quote

Reply With Quote